Hered ZL112 and ZL212 Multistage Vacuum Generators

The Hered ZL112 and ZL212 are advanced multistage ejector vacuum generators designed for efficient and reliable vacuum generation in various industrial applications. These models offer improved performance, energy efficiency, and ease of maintenance.

ZL112 Key Features

- Suction Flow Rate: Up to 100 L/min (ANR)

- Weight: Approximately 180 grams (60% reduction from previous models)

- Air Consumption: Up to 91% reduction in some configurations

- 3-Stage Diffuser: 250% increase in suction flow rate

- Tool-free Maintenance: Simplified upkeep and reduced labor costs

- IO-Link Compatible: Enhanced monitoring capabilities

ZL212 Highlights

- Higher Suction Flow Rate: Suitable for larger applications

- Multistage Design: Improved efficiency and reduced air consumption

- Lightweight Construction: Easy installation and handling

- Tool-free Maintenance: Consistent with ZL112 model

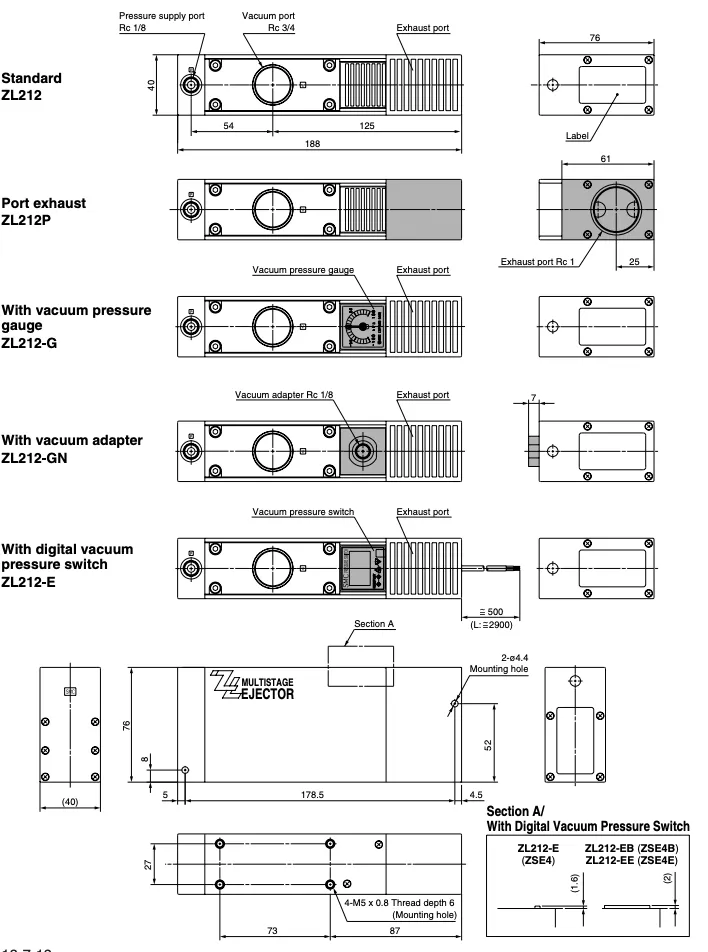

Dimension

Ejector Specifications

| Model | ZL112 |

|---|---|

| Nozzle diameter | ø1.2 mm |

| Maximum suction flow rate | 100 ℓ/min (ANR) |

| Air consumption | 63 ℓ/min (ANR) |

| Maximum vacuum pressure | -84 kPa |

| Maximum operating pressure | 0.7 MPa |

| Supply pressure range | 0.2 to 0.5 MPa |

| Standard supply pressure | 0.4 MPa |

| Operating temperature range | 5 to 50°C |

Supply/Release Valve Specifications

| Part no. | SYJ514-□□□ |

|---|---|

| Type of valve actuation | N.C. |

| Fluid | Air |

| Operating pressure range Internal pilot type | 0.2 to 0.5 MPa |

| Ambient and fluid temperature | 5 to 50°C |

| Response time (For 0.5 MPa) | 25 ms or less |

| Maximum operating frequency (1) | 5 Hz |

| Manual override | Non-locking push type/Locking slotted type |

| Pilot exhaust type | Pilot valve individual exhaust, Main valve/Pilot valve common exhaust |

| Lubrication | Not required |

| Mounting position | Unrestricted |

| Impact/Vibration resistance | 150/30 m/s2 |

| Enclosure (2) | Dust proof |

Note 1) Based on JIS B 8374-1981 dynamic performance test. (coil temperature 20°C, at rated voltage, without surge voltage suppressor)

Note 2) Impact resistance: No malfunction when tested with a drop tester in the axial direction and at a right angle to the main valve and armature, one time each in both energized and deenergized states. (initial value)

Vibration resistance: No malfunction when tested with one sweep of 45 to 2000 Hz in the axial direction and at a right angle to the main valve and armature, one time each in both energized and deenergized states. (initial value)

Note 3) Refer to “Best Pneumatics Vol. 4” for details on valves.

Common Advantages

| Feature | Benefit |

|---|---|

| Multistage Ejector Design | Enhanced performance and energy efficiency |

| Lightweight Construction | Easy installation and reduced strain on mounting points |

| Reduced Air Consumption | Lower operational costs and energy savings |

| Simplified Maintenance | Reduced downtime and maintenance costs |

Applications

- Material Handling Systems

- Packaging Processes

- Automation Equipment

- Pick-and-Place Operations

Technical Advantages

- Improved Efficiency: Multistage design optimizes vacuum generation

- Compact Size: Ideal for space-constrained installations

- Versatile Performance: Suitable for various industrial applications

- Energy Saving: Reduced air consumption lowers operational costs

The Hered ZL112 and ZL212 Vacuum Generators offer cutting-edge solutions for industries requiring efficient and reliable vacuum generation. Their advanced design, coupled with energy-saving features and easy maintenance, makes them excellent choices for modern manufacturing and automation environments.