Overview

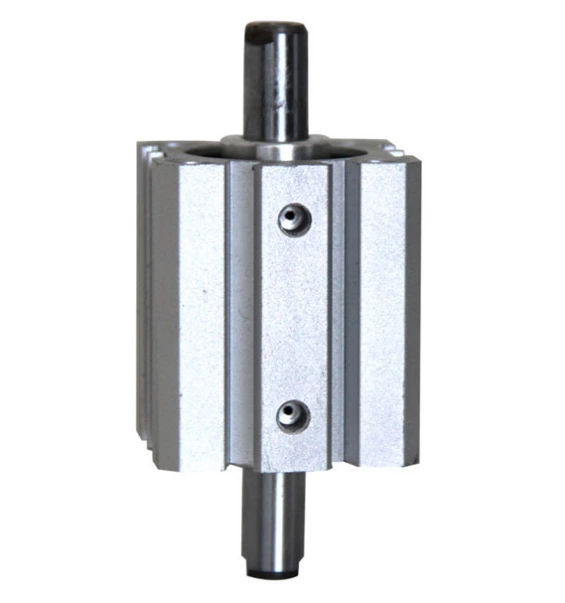

The SDAD Compact Pneumatic Cylinder from Hered Pneumatic Co., LTD. is a high-performance, double-rod air cylinder designed using the AirTAC standard. Manufactured with precision and durability in mind, this cylinder is ideal for applications requiring compact and reliable pneumatic solutions.

Specifications

- Brand: Hered Pneumatic

- Place of Origin: China

- Sizes: 12, 16, 20, 25, 32, 40, 50, 63, 80, 100 mm

- Lengths: 5, 10, 15, 20, 25, 30, 35, 40, 45, 50, 75, 100, 110, 120, 130 mm

- Operating Pressure: 0.1-1.0 MPa / 0.2-1.0 MPa

- Working Environment Temperature: -10 to 80°C

- Speed: 30-500 mm/s; 50-500 mm/s

Description

The SDAD Double Rod Compact Air Cylinder is engineered for high durability and space efficiency. The cylinder’s body and rear cover, along with the piston and piston rod, have a riveted construction for enhanced reliability. The inner diameter is processed by rolling and treated with hard oxidation for superior wear resistance.

The special two-way piston seal design allows for compact sizing while providing an oil storage function. This structure helps in conserving installation space. The cylinder body also features grooves for easy mounting of magnetic induction switches, simplifying the installation and position adjustment process.

Key Features

- High Durability: Hard-oxidized inner diameter for increased wear resistance.

- Space Efficiency: Compact structure saves significant installation space.

- Easy Installation: Embedded grooves for magnetic induction switches facilitate quick and convenient setup.

- Smooth Operation: Piston seal structures enable efficient operation with oil storage capability.

Installation Instructions

- Store cylinders in a ventilated and dry warehouse to prevent moisture and rust.

- Test the cylinder under no-load conditions before installation.

- Select the installation form according to the usage conditions:

- Earrings and Intermediate Shaft Pin Installation: Ensure forces are in the same plane.

- Flange Installation: Align forces with the bearing center axis; ensure the flange surface bears the force.

- Ultra Long Stroke Cylinders: Add a bearing or guiding device to avoid partial or lateral loads on the piston rod.

- Clean the pipeline before connecting to the cylinder to prevent debris or dust ingress.

- Adjust the buffer core if necessary to avoid collision between the piston and cylinder head.

- Regularly check fasteners to prevent loosening during use.

- Install one-way throttle valves in the inlet and exhaust pipes to regulate the piston rod’s movement speed.

Applications

The SDAD Compact Pneumatic Cylinder is suitable for use in:

- Automated manufacturing systems

- Robotic arm mechanisms

- Material handling equipment

- Precision machining tools

- Other industrial automation applications

Hered Pneumatic Co., LTD. provides the SDAD Compact Pneumatic Cylinder as a robust, space-saving, and versatile solution to meet your industrial pneumatics needs.