MPT Series Air & Liquid Increasing Pressure Cylinder

The MPT Series Air & Liquid Increasing Pressure Cylinder is a specialized pneumatic actuator designed for enhanced pressure control in various industrial processes. It offers dual functionality for both air and liquid applications, making it a versatile solution for different scenarios requiring increased pressure output.

Key Features

- Dual Functionality: Handles both air and liquid

- Pressure Increase Mechanism: Designed to amplify pressure output

- Compact Design: Easy integration into existing systems

- Robust Construction: Built for high-pressure environments

- Wide Range of Applications: Suitable for various industries

- Customization Options: Multiple configurations available

Specifications

| Parameter | Specification |

|---|---|

| Bore size(mm) | MPT |

| Action | Double acting type |

| Fluid | Air(filtered through 40μ filter element) |

| Operating pressure | 0.2~0.7Mpa(2~7kgf/cm²) |

| Lubrication | ISO VG68 |

| Ambient & fluid temperature | -5~+60°C |

| Operating speed | 50~700mm/s |

| Proof pressure | Cylinder 300kgf/cm² Air cylinder:kgf/cm² |

| Frequency | 10 times/min |

Performance Data

The relationship between stroke size and output is detailed in the provided table, which includes information on cylinder diameter, tonnage, total travel, booster travel, working pressure, and various output values for different pressure levels.

| The relationship between stroke size and contribute to the table | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Cylinder diameter (mm) | Tonnage T | Total travel (mm) | Booster travel (mm) | Working pressure (kgf/cm²) | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| 63 | 1 | 50 100 150 200 |

5 10 15 20 | Preload Output Kg Booster Output Kg Return Rally Kg |

30 300 20 |

60 600 40 |

90 900 60 |

120 1250 80 |

150 1550 100 |

180 1850 120 |

210 2150 140 |

| 3 | 50 100 150 200 |

Preload Output Kg Booster Output Kg Return Rally Kg |

30 500 20 |

60 1000 40 |

90 1500 60 |

120 2000 80 |

150 2500 100 |

180 3000 120 |

210 3500 140 |

||

| 80 | 5 | 50 100 150 200 |

5 10 15 20 | Preload Output Kg Booster Output Kg Return Rally Kg |

50 1000 40 |

100 2000 80 |

150 3000 120 |

200 4000 160 |

250 5000 200 |

300 6000 240 |

350 7000 280 |

| 100 | 10 | 50 100 150 200 |

5 10 15 20 | Preload Output Kg Booster Output Kg Return Rally Kg |

78 1560 60 |

156 3120 120 |

234 4680 180 |

312 6240 240 |

390 7800 300 |

468 9360 360 |

546 10920 420 |

| 13 | 50 100 150 200 |

Preload Output Kg Booster Output Kg Return Rally Kg |

78 1970 60 |

156 3940 120 |

234 5190 180 |

312 7880 240 |

390 9850 300 |

468 11820 360 |

546 13790 420 |

||

| 125 | 15 | 50 100 150 200 |

5 10 15 20 | Preload Output Kg Booster Output Kg Return Rally Kg |

120 2560 90 |

240 5120 180 |

360 7680 270 |

480 10240 360 |

600 12800 450 |

720 15350 540 |

840 17900 630 |

| 20 | 50 100 150 200 |

Preload Output Kg Booster Output Kg Return Rally Kg |

120 3500 90 |

240 7000 180 |

360 10500 270 |

480 14000 360 |

600 17500 450 |

720 21000 540 |

840 24500 630 |

||

| 30 | 50 100 150 200 |

Preload Output Kg Booster Output Kg Return Rally Kg |

120 4000 90 |

240 8000 180 |

360 12000 270 |

480 16000 360 |

600 20000 450 |

720 24000 540 |

840 28000 630 |

||

| 160 | 40 | 50 100 150 200 |

5 10 15 20 | Preload Output Kg Booster Output Kg Return Rally Kg |

200 6500 165 |

400 13000 330 |

600 19500 495 |

800 26000 660 |

1000 32500 825 |

1200 39000 990 |

1400 46000 1155 |

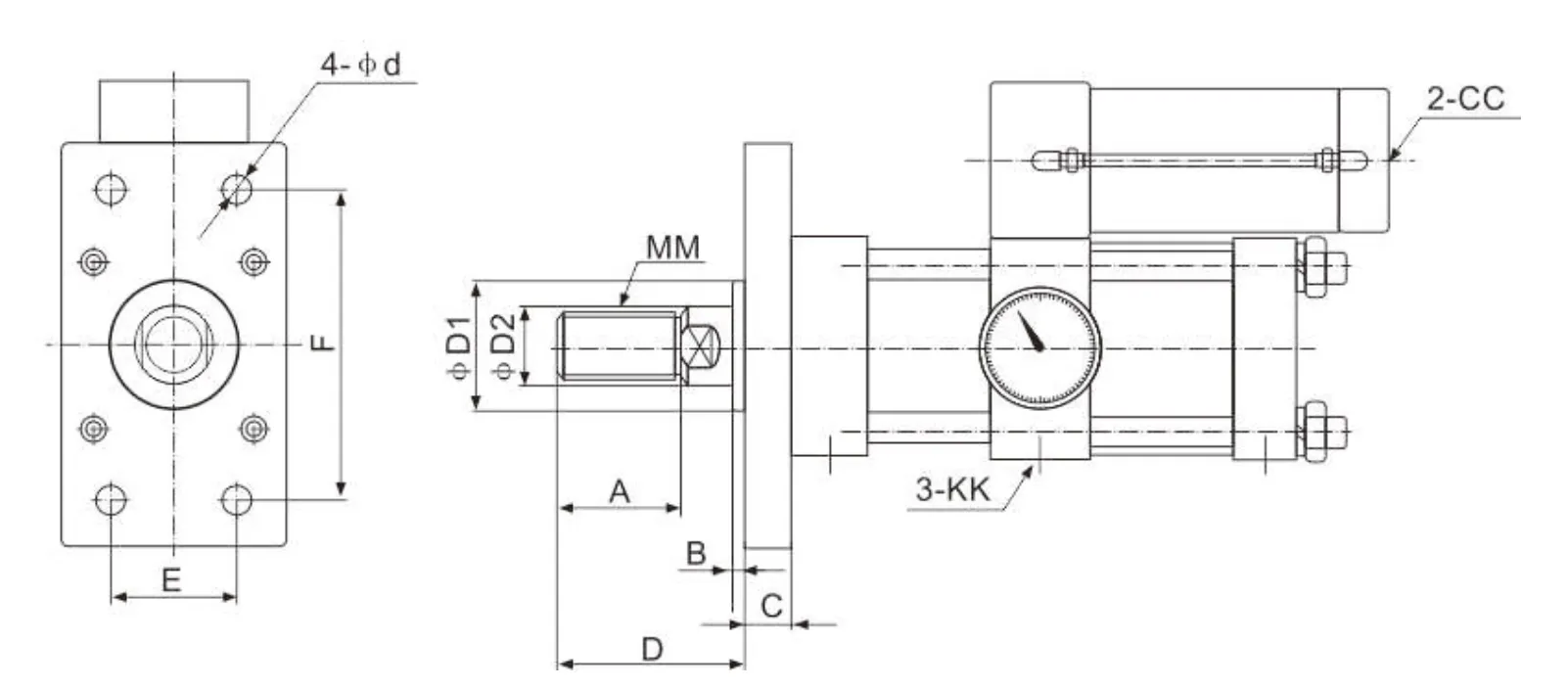

Dimensions

The product is available in various tonnage ratings from 1T to 40T, with corresponding dimensions for different components such as A, B, C, D, E, d, MM, KK, and CC. Please refer to the dimension table for specific measurements based on tonnage.

| Tonnage | A | B | C | D | D1 | D2 | E | d | MM | KK | CC | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1T | 50 | 5 | 20 | 75 | 46 | 35 | 65 | 132 | 14 | M30X1.5 | G3/8 | G3/8 |

| 3T | 50 | 5 | 20 | 75 | 55 | 35 | 65 | 132 | 14 | M30X1.5 | G3/8 | G3/8 |

| 5T | 50 | 5 | 20 | 90 | 55 | 35 | 87 | 155 | 17 | M30X1.5 | G3/8 | G3/8 |

| 10T | 55 | 5 | 30 | 90 | 65 | 45 | 110 | 190 | 21 | M39X2 | G1/2 | G3/8 |

| 13T | 55 | 5 | 30 | 90 | 65 | 45 | 110 | 190 | 21 | M39X2 | G1/2 | G3/8 |

| 15T | 55 | 5 | 30 | 90 | 75 | 55 | 140 | 255 | 25 | M48X2 | G1/2 | G3/8 |

| 20T | 55 | 5 | 30 | 90 | 77 | 60 | 140 | 255 | 25 | M48X2 | G1/2 | G3/8 |

| 30T | 55 | 5 | 30 | 90 | 60 | 175 | 290 | 30 | M48X2 | G3/4 | G1/2 | |

| 40T | 55 | 5 | 40 | 90 | 60 | 175 | 290 | 38 | M48X2 | G3/4 | G1/2 |

Applications

- Manufacturing processes

- Automotive industry

- Fluid control systems

- Hydraulic and pneumatic systems

- Automated production lines

For detailed performance data and dimensions, please consult the specific tables provided or contact our technical support team for assistance in selecting the right configuration for your application.