Hered AKB Metal Check Valve Series

Hered Pneumatic Co., LTD.’s AKB Metal Check Valve Series with One Touch Fitting offers a quick and efficient solution for air piping and pneumatic tool connections. These valves ensure one-way flow, maintaining system integrity and efficiency in various pneumatic applications.

Key Features

- One-way operation prevents backflow

- Durable metal construction for corrosion and wear resistance

- One-touch fitting for quick and easy installation

- Available in various port sizes and models

- Suitable for air, gas, and other process fluids

Specifications

- Port Sizes: PT1/8, PT1/4, PT3/8, PT1/2

- Available in A-type (male to female thread flow) and B-type (female to male thread flow)

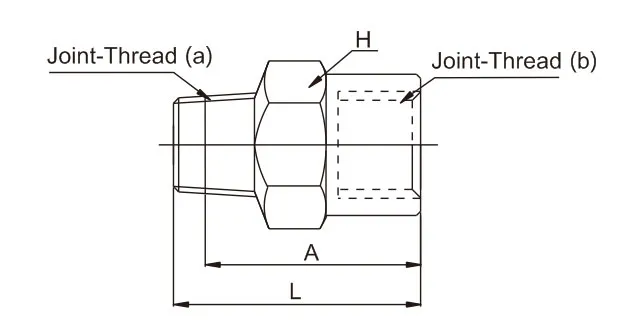

Dimensions

| Model | Joint-Thread (a) | Joint-Thread (b) | L | A | H | |

| A-type | B-type | |||||

| AKB01-01A | AKB01-01B | PT1/8 | G1/8 | 23.8 | 20.7 | 14 |

| AKB01-02A | AKB01-02B | PT1/4 | G1/8 | 23.8 | 20.7 | 14 |

| AKB02-02A | AKB02-02B | PT1/4 | G1/4 | 23.8 | 20.7 | 14 |

| AKB03-03A | AKB03-03B | PT3/8 | G3/8 | 45.2 | 38.7 | 22 |

| AKB04-04A | AKB04-04B | PT1/2 | G1/2 | 56.2 | 48.2 | 24 |

Usage Guidelines

- Ensure proper space for pipeline installation and commissioning

- Clean hoses and fittings with compressed air before installation

- Arrange wiring neatly, with proper grouping and numbering

- Consider working environment temperature for hose reliability

- Optimize hose length to minimize air pressure loss

- Avoid excessive bending near joints to prevent leakage

- Use appropriate tightening torque for threaded pipe joints

Applications

- Pneumatic circuits and systems

- Air piping installations

- Pneumatic tools and equipment

- Industrial automation processes

Benefits

- Enhances system efficiency by preventing backflow

- Quick and tool-free installation and removal

- Durable construction for long-term reliability

- Versatile design suitable for various pneumatic applications

For detailed specifications, model options, or customized solutions, please contact our technical support team. Our engineers are ready to assist you in selecting the optimal AKB Metal Check Valve for your specific pneumatic system requirements.