Hered MAL Series Mini Pneumatic Cylinder

Hered Pneumatic Co., LTD.’s MAL Series Mini Pneumatic Cylinder is a compact, high-performance actuator designed for various industrial applications. Featuring stable output torque and power, this cylinder offers exceptional durability, temperature resistance, and versatile installation options.

Key Features

- No lubrication required due to oil-containing powder metallurgy copper axle bearings

- Anodic hard oxidation treatment for enhanced corrosion resistance

- High-temperature sealing material allows operation up to 150°C

- Multiple installation modes available

- Magnetic piston for position sensing with induction switches

- Aluminum alloy construction for lightweight and efficient cooling

Inner structure and material of major parts

| No. | Item | Material | No. | Item | Material |

| 1 | Rod nut | Carbon steel | 9 | Bumoer | NBR |

| 2 | Piston rod | Carbon steel with 20μm chrome plated | 10 | O-ring | NBR |

| 3 | Front cover packing | NBR | 11 | Piston seal | NBR |

| 4 | Bushing | Wear resistant material | 12 | Piston | Aluminium alloy |

| 5 | Front cover nut | Carbon steel | 13 | Wear ring | Wear resistant material |

| 6 | Front cover | Aluminium alloy | 14 | Washer | Free cutting material |

| 7 | O-ring | NBR | 15 | Bolt | Carbon steel |

| 8 | Barrel | Aluminium alloy | 16 | Back cover | Aluminium alloy |

Specifications

| Bore (mm) | 20 | 25 | 32 | 40 | |

| Motion Pattern | MSAL/MTAL | Single-acting | |||

| Other | Double-acting | ||||

| Working Medium | Air | ||||

| Operating Pressure | Double-acting | 0.1~1.0MPa(14~145Psi) | |||

| Single-acting | 0.2~1.0MPa(28~145Psi) | ||||

| Proof Pressure | 1.5MPa(215Psi) | ||||

| Operating Temperature | -20~70°C | ||||

| Operating Speed | Single-acting: 50~800mm/s; Double-acting: 30~800mm/s | ||||

| Stroke Tolerance | 0~150 (+1.0/0) >150(+1.4/0) | ||||

| Cushion Type | Bumper | ||||

| Port Size | PT1/8 | PT1/4 | |||

Stroke for MAL Cylinder

| Bore (mm) | Standard Stroke (mm) | Max. Stroke | Allowable Stroke | |

| MAL | 20 | 25 50 75 80 100 125 150 160 175 200 250 300 | 500 | 800 |

| 25 | 25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 | 800 | 1200 | |

| 32 | 800 | 1200 | ||

| 40 | 1200 | 1500 | ||

| MSAL | 20 | 25 50 75 80 100 125 150 | 150 | – |

| 25 | 150 | – | ||

| 32 | 150 | – | ||

| 40 | 150 | – | ||

| MTAL | 20 | 25 50 75 80 100 | 100 | – |

| 25 | 100 | – | ||

| 32 | 100 | – | ||

| 40 | 100 | – | ||

| MALD MALJ |

20 | 25 50 75 80 100 125 150 160 175 200 | 200 | 300 |

| 25 | 25 50 75 80 100 125 150 160 175 200 250 | 250 | 300 | |

| 32 | 250 | 300 | ||

| 40 | 250 | 300 | ||

Ordering Code for MAL Mini Pneumatic Cylinder

Ordering Code for MAL Mini Pneumatic Cylinder

Overall Dimension for MAL Mini Air Cylinder

| Bore/Symbol | A | A1 | A2 | B | C | D | D1 | E | F | G | H | I | J | K | L | M | P | Q | R | R1 | S | U | V | W | X | AR | AX | AY |

| 20 | 131 | 122 | 110 | 40 | 70 | 21 | 12 | 28 | 12 | 16 | 20 | 12 | 6 | M8×1.25 | M22×1.5 | 10 | 8 | 16 | 19 | 10 | 12 | 29 | 8 | 6 | PT1/8 | 7 | 33 | 29 |

| 25 | 135 | 128 | 114 | 44 | 70 | 21 | 14 | 30 | 14 | 16 | 22 | 17 | 6 | M10×1.25 | M22×1.5 | 12 | 8 | 16 | 19 | 12 | 12 | 34 | 10 | 8 | PT1/8 | 7 | 33 | 29 |

| 32 | 141 | 128 | 114 | 44 | 70 | 27 | 14 | 30 | 14 | 16 | 22 | 17 | 6 | M10×1.25 | M24×2.0 | 12 | 10 | 16 | 25 | 12 | 15 | 39.5 | 12 | 10 | PT1/8 | 8 | 37 | 32 |

| 40 | 165 | 152 | 138 | 46 | 92 | 27 | 14 | 32 | 14 | 22 | 24 | 17 | 7 | M12×1.25 | M30×2.0 | 12 | 12 | 20 | 25 | 12 | 15 | 49.5 | 16 | 14 | PT1/4 | 9 | 47 | 41 |

| Bore/Symbol | A | A1 | A2 | B | C | D | D1 | E | F | G | H | I | J | K | L | M | P | Q | R | S | U | V | W | X | AR | AX | AY | ||||||||

| 0~50 | 51~100 | ≥101 | 0~50 | 51~100 | ≥101 | 0~50 | 51~100 | ≥101 | 0~50 | 51~100 | ≥101 | ||||||||||||||||||||||||

| 20 | 156 | 181 | 206 | 147 | 172 | 197 | 135 | 160 | 185 | 40 | 95 | 120 | 145 | 21 | 12 | 28 | 12 | 16 | 20 | 12 | 6 | M8×1.25 | M22×1.5 | 10 | 8 | 16 | 19 | 12 | 29 | 8 | 6 | PT1/8 | 7 | 33 | 29 |

| 25 | 160 | 185 | 210 | 153 | 178 | 203 | 139 | 164 | 189 | 44 | 95 | 120 | 145 | 21 | 14 | 30 | 14 | 16 | 22 | 17 | 6 | M10×1.25 | M22×1.5 | 12 | 8 | 16 | 19 | 12 | 34 | 10 | 8 | PT1/8 | 7 | 33 | 29 |

| 32 | 166 | 191 | 216 | 153 | 178 | 203 | 139 | 164 | 189 | 44 | 95 | 120 | 145 | 27 | 14 | 30 | 14 | 16 | 22 | 17 | 6 | M10×1.25 | M24×2.0 | 12 | 10 | 16 | 25 | 15 | 39.5 | 12 | 10 | PT1/8 | 8 | 37 | 32 |

| 40 | 190 | 215 | 240 | 177 | 202 | 227 | 163 | 188 | 216 | 46 | 117 | 142 | 167 | 27 | 14 | 32 | 14 | 22 | 24 | 17 | 7 | M12×1.25 | M30×2.0 | 12 | 12 | 20 | 25 | 15 | 49.5 | 16 | 14 | PT1/4 | 9 | 47 | 41 |

| Bore/Symbol | A | A1 | A2 | C | ||||||||||||

| 0~25 | 26~50 | 51~75 | 76~100 | 0~25 | 26~50 | 51~75 | 76~100 | 0~25 | 26~50 | 51~75 | 76~100 | 0~25 | 26~50 | 51~75 | 76~100 | |

| 20 | 146 | 156 | 171 | 181 | 137 | 147 | 162 | 172 | 125 | 135 | 150 | 160 | 85 | 95 | 110 | 120 |

| 25 | 150 | 160 | 175 | 185 | 143 | 153 | 168 | 178 | 129 | 139 | 154 | 164 | 85 | 95 | 110 | 120 |

| 32 | 156 | 166 | 186 | 196 | 143 | 153 | 173 | 183 | 129 | 139 | 159 | 169 | 85 | 95 | 115 | 125 |

| 40 | 180 | 190 | 210 | 220 | 167 | 177 | 197 | 207 | 153 | 163 | 183 | 193 | 107 | 117 | 137 | 147 |

| Bore/Symbol | A | B | C | E | F | G | H | I | J | K | L | M | U | V | W | X | AR | AX | AY |

| 20 | 150 | 40 | 70 | 28 | 12 | 16 | 20 | 12 | 6 | M8×1.25 | M22×1.5 | 10 | 29 | 8 | 6 | PT1/8 | 7 | 33 | 29 |

| 25 | 158 | 44 | 70 | 30 | 14 | 16 | 22 | 17 | 6 | M10×1.25 | M22×1.5 | 12 | 34 | 10 | 8 | PT1/8 | 7 | 33 | 29 |

| 32 | 158 | 44 | 70 | 30 | 14 | 16 | 22 | 17 | 6 | M10×1.25 | M24×2.0 | 12 | 39.5 | 12 | 10 | PT1/8 | 8 | 37 | 32 |

| 40 | 184 | 46 | 92 | 32 | 14 | 22 | 24 | 17 | 7 | M12×1.25 | M30×2.0 | 12 | 49.5 | 16 | 14 | PT1/4 | 9 | 47 | 41 |

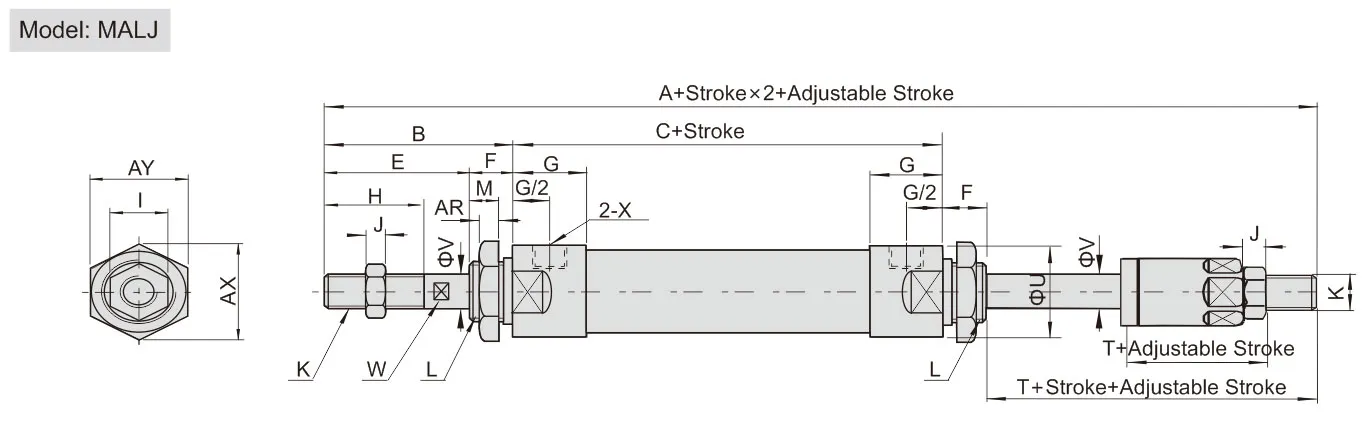

| Bore/Symbol | A | B | C | E | F | G | H | I | J | K | L | M | T | U | V | W | X | AR | AX | AY |

| 20 | 147 | 40 | 70 | 28 | 12 | 16 | 20 | 12 | 6 | M8×1.25 | M22×1.5 | 10 | 19 | 29 | 8 | 6 | PT1/8 | 7 | 33 | 29 |

| 25 | 155 | 44 | 70 | 30 | 14 | 16 | 22 | 17 | 6 | M10×1.25 | M22×1.5 | 12 | 21 | 34 | 10 | 8 | PT1/8 | 7 | 33 | 29 |

| 32 | 155 | 44 | 70 | 30 | 14 | 16 | 22 | 17 | 6 | M10×1.25 | M24×2.0 | 12 | 21 | 39.5 | 12 | 10 | PT1/8 | 8 | 37 | 32 |

| 40 | 180 | 46 | 92 | 32 | 14 | 22 | 24 | 17 | 7 | M12×1.25 | M30×2.0 | 12 | 21 | 49.5 | 16 | 14 | PT1/4 | 9 | 47 | 41 |

Construction

The MAL cylinder features an aluminum alloy body with threaded connections between front/back covers and the cylinder tube. The piston uses a heterogenous two-way seal structure for compact size and grease reservation. The front cover includes a self-lubrication bearing guide for smooth operation.

Applications

- Industrial automation

- Packaging machinery

- Assembly equipment

- Material handling systems

- Automotive manufacturing

Benefits

- Stable output torque and power

- Improved acceleration response in multi-cylinder configurations

- Durable and corrosion-resistant design

- High-temperature operation capability

- Flexible installation options

- Position sensing capability

For detailed specifications, model options, or customized solutions, please refer to the provided dimension tables and ordering codes. Our technical support team is available to assist you in selecting the optimal MAL Series Mini Pneumatic Cylinder for your specific application requirements.