Hered C(D)U Free Mount Installation Double Acting Pneumatic Air Cylinder

The Hered C(D)U Free Mount Installation Double Acting Pneumatic Air Cylinder is a versatile and efficient actuator designed for various industrial applications. This series features a compact and flexible design, allowing for direct mounting on multiple surfaces, which optimizes installation space and enhances operational flexibility.

Key Features

- Free Mount Installation: Can be mounted directly on multiple sides for flexible positioning

- Double Acting: Operates in both directions for effective linear motion control

- Versatile Sizing: Available in various bore sizes, typically from 6 mm to 32 mm

- Customizable Stroke Lengths: Adaptable to specific application requirements

- Auto Switch Compatibility: Designed to accommodate auto switches for enhanced automation

- Durable Construction: Built with high-quality materials for industrial environments

- Cushioning Options: Available features to reduce impact and improve operation smoothness

Applications

- Automated Assembly Lines

- Packaging Systems

- Material Handling Equipment

- Industrial Automation Processes

- Robotic Systems

- Manufacturing Equipment

Technical Specifications

| Bore(mm) | 6 | 10 | 16 | 20 | 25 | 32 | ||

| Working Medium | Clean Air(40μm Filteration) | |||||||

| Acting Type | Double Acting/Single Acting | |||||||

| Min Pressure (Mpa) |

Double acting | Single piston rod | 0.12 | 0.06 | 0.05 | |||

| Double piston rod | 0.15 | 0.1 | 0.08 | |||||

| Double piston rod | 0.18 | 0.13 | 0.11 | |||||

| Single acting | Standard | 0.2 | 0.15 | 0.13 | ||||

| Non-rotating | 0.23 | 0.18 | 0.16 | |||||

| Max Pressure | 0.7Mpa | |||||||

| Working Temperature | 5~60°C | |||||||

| Cushion Type | Rubber Cushion | |||||||

| Stroke Tolerance(mm) | ±0.1 | |||||||

| Lubrication | Not required | |||||||

| Installation | Free | |||||||

| Non-rotating accuracy | ±0.8° | ±0.5° | ||||||

| Port Size | M5x0.8 | G1/8 | ||||||

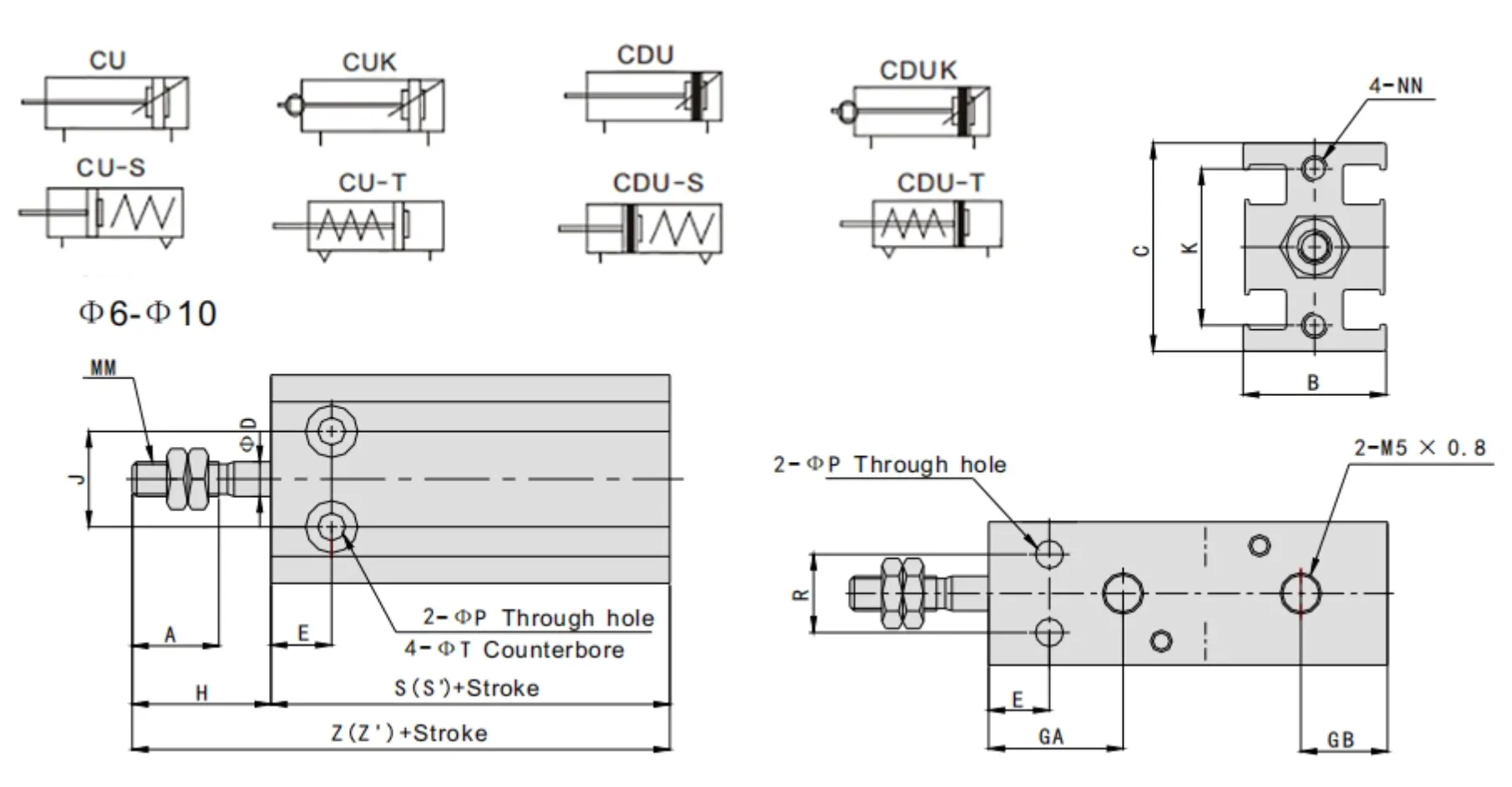

Dimension

Common Dimensions Table

| Model | A | A1 | B | C | ΦD | E | GA | GB | J | K | L | MM | NN | ΦP | Q | R | ΦT |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CU6 | 7 | – | 13 | 22 | 3 | 7 | 14.5 | 10 | 10 | 17 | – | M3X0.5 | M3X0.5Depth5 | 3.2 | – | 7 | 6Depth4.8 |

| CU10 | 10 | – | 15 | 24 | 4 | 7 | 15.5 | 10 | 11 | 18 | – | M4X0.7 | M3X0.5Depth5 | 3.2 | – | 9 | 6Depth5 |

| CU16 | 11 | 12.5 | 20 | 32 | 6 | 7 | 16.5 | 11.5 | 14 | 25 | 5 | M5X0.8 | M4X0.7Depth6 | 4.5 | 4 | 12 | 7.6Depth6.5 |

| CU20 | 12 | 14 | 26 | 40 | 8 | 9 | 19 | 12.5 | 16 | 30 | 6 | M6X1.0 | M5X0.8Depth8 | 5.5 | 9 | 16 | 9.3Depth8 |

| CU25 | 15.5 | 18 | 32 | 50 | 10 | 10 | 21.5 | 13 | 20 | 38 | 8 | M8X1.25 | M5X0.8Depth8 | 5.5 | 9 | 20 | 9.3Depth9 |

| CU32 | 19.5 | 22 | 40 | 62 | 12 | 11 | 23 | 13 | 24 | 48 | 10 | M10X1.25 | M6X1.0Depth9 | 6.6 | 13.5 | 24 | 11Depth11.5 |

Double Acting

| Model | H | Standard | With Magnet | |||

|---|---|---|---|---|---|---|

| S | Z | W | S’ | Z’ | ||

| CU6-D | 13 | 33 | 46 | 2.5 | 33 | 46 |

| CU10-D | 16 | 36 | 52 | 1 | 36 | 52 |

| CU16-D | 16 | 30 | 46 | 0 | 40 | 56 |

| CU20-D | 19 | 36 | 55 | 1 | 46 | 65 |

| CU25-D | 23 | 40 | 63 | -1 | 50 | 73 |

| CU32-D | 27 | 42 | 69 | -4 | 52 | 79 |

Single Acting(with Spring Return)

| Model | H | Standard | W | With Magnet | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S | Z | S’ | Z’ | |||||||||||

| 5st | 10st | 15st | 5st | 10st | 15st | 5st | 10st | 15st | 5st | 10st | 15st | |||

| CU6-S | 13 | 38 | 43 | 48 | 51 | 56 | 61 | 2.5 | 38 | 43 | 48 | 51 | 56 | 61 |

| CU10-S | 16 | 41 | 46 | 56 | 57 | 62 | 72 | 1 | 41 | 46 | 56 | 57 | 62 | 72 |

| CU16-S | 16 | 35 | 40 | 50 | 51 | 56 | 66 | 0 | 45 | 50 | 60 | 61 | 66 | 76 |

| CU20-S | 19 | 41 | 46 | 56 | 60 | 65 | 75 | 1 | 51 | 56 | 66 | 70 | 75 | 85 |

| CU25-S | 23 | 45 | 50 | 60 | 68 | 73 | 83 | -1 | 55 | 60 | 70 | 78 | 83 | 93 |

| CU32-S | 27 | 47 | 52 | 62 | 74 | 79 | 89 | -4 | 57 | 62 | 72 | 84 | 89 | 99 |

Benefits

- Space Optimization: Compact design ideal for confined spaces

- Installation Flexibility: Multiple mounting options for diverse applications

- Operational Efficiency: Double-acting mechanism for precise control

- Customization: Various sizes and stroke lengths to meet specific needs

- Enhanced Automation: Auto switch compatibility for improved process control

- Reliability: Durable construction for long-term industrial use

- Smooth Operation: Cushioning options available for reduced noise and impact

Optional Features

- Cushioning mechanisms for smoother end-of-stroke operation

- Various seal materials for different environmental conditions

- Special coatings for enhanced corrosion resistance

The Hered C(D)U Free Mount Installation Double Acting Pneumatic Air Cylinder represents a significant advancement in pneumatic actuation technology. Its versatile design and robust performance make it an excellent choice for a wide range of industrial applications where space efficiency, flexibility, and reliable operation are crucial.

For more detailed specifications, customization options, or to discuss how the C(D)U series can benefit your specific application, please contact our Hered technical support team. We’re committed to providing you with the best pneumatic solutions tailored to your needs.