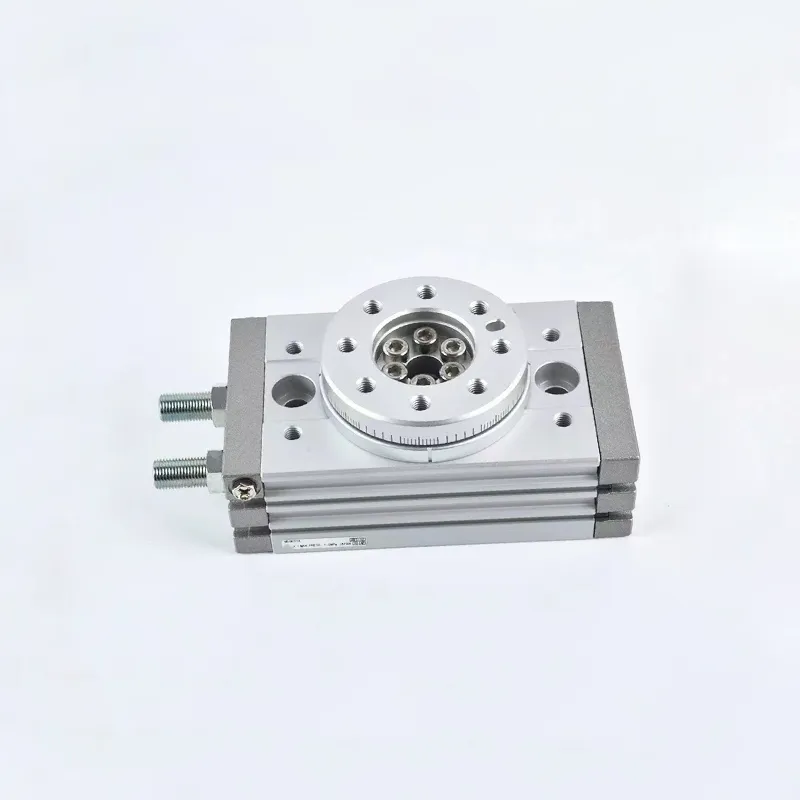

Hered MSQ Series Rotary Tables

Hered Pneumatic Co., LTD.’s MSQ Series Rotary Tables are high-precision, gear-rack type pneumatic actuators designed for various material transfer and positioning applications. With multiple bore sizes and a wide angle adjustment range, these rotary tables offer exceptional performance and flexibility in industrial automation systems.

Key Features

- High-precision ball bearings for improved vertical and horizontal accuracy (±0.01mm)

- Easy workpiece installation with rotary table design

- Roller bearing design for 3-4 times higher load capacity than CRQ series

- Smooth and accurate rotational movement

- Hollow shaft for wire or air line integration

- Standard angle adjustment device (0-190°)

- Built-in magnetic ring for magnetic switch compatibility

- Compact and lightweight design

- Enlarged center hole for efficient piping (new models)

Specifications

| Bore (mm) | 10 | 20 | 30 | 50 | 70 | 100 | 200 | |

| Working Medium | Air (Non-lube) | |||||||

| Motion Pattern | Double-acting | |||||||

| Max. Operating Pressure | Angle adjusting screw | 1MPa | ||||||

| Hydraulic buffer | 0.6MPa | |||||||

| Min. Operating Pressure | 0.1MPa(High-precision type: 10 for 0.2MPa,20~50 for 0.1MPa) | |||||||

| Ambient and fluid temp. | 0~60℃ (No Freezing) | |||||||

| Buffer | Rubber buffer (standard)/Hydraulic buffer (optional) | |||||||

| Allowable kinetic energy | Angle adjusting screw | 0.007J | 0.025J | 0.048J | 0.081J | 0.24J | 0.32J | 0.56J |

| Hydraulic buffer | 0.039J | 0.116J | 0.294J | 1.1J | 1.6J | 2.9J | ||

| Angle adjustment range | 0~190° | |||||||

| Max. swing angle | 190° | |||||||

| Stable swing time range | Angle adjusting screw | 0.2~1.0s/90° | 0.2~1.5s/90° | 0.2~2.0s/90° | 0.2~2.5s/90° | |||

| Hydraulic buffer | 0.2~0.7s/90° | 0.2~1.0s/90° | ||||||

| Bore | Φ15 | Φ18 | Φ21 | Φ25 | Φ28 | Φ32 | Φ40 | |

| APort Size | M5×0.8 | Rc1/8 | ||||||

Ordering Code for MSQ Rotary Tables

Dimension

| Model | DA | DB | DC | DD | HA | HB | HD |

| MSQA10□ | 46H8 | 45H8 | 20H8 | 15H8 | 10 | 18.5 | 52.5 |

| MSQA20□ | 61H8 | 60h8 | 28H8 | 17H8 | 15.5 | 26 | 63 |

| MSQA30□ | 67H8 | 65h8 | 32H8 | 22H8 | 16.5 | 27 | 67 |

| MSQA50□ | 77H8 | 75h8 | 35H8 | 26H8 | 17.5 | 30 | 76 |

| Model | Adjusting angle per 1 turn* |

| MSQB10□ | About 10.2° |

| MSQB20□ | About 7.2° |

| MSQB30□ | About 6.5° |

| MSQB40□ | About 8.2° |

* Refers to the case of the angle adjustment screw or hydraulic buffer per 1 turn.

Note: The maximum size is when the swing angle is at maximum (190 °).

| Model | A | B | C | D | E | F | G | H | I | J | K | L | M | N | O | P | Q | R | S | T | U | V | W | X | Y | Z | AA | BB | CC | DD | EE | FF | GG | HH | II | JJ | KK | LL | MM | NN | OO | PP | RR | SS | TT | Hydraulic buffer | |

| MSQB10□ | 60 | 27 | 15 | 2 | M5×0.8 | 8 | M5×0.8 | 6.8 | 11 | 6.5 | 3H9 | 3.5 | 32 | 93 | 15H9 | 5 | 9.5 | 8.6 | 17.7 | 47 | 34 | 4.5 | 3 | 13 | 8 | 4 | 46 | 45 | 20 | M8×1.25 | 12 | M8×1 | 50 | 45 | 20 | 12 | 4 | 27.8 | 15.5 | 34.5 | 9 | 13 | M5×0.8 | 31.5 | 8.6 | M8×1 | RBA0805-X692 |

| MSQB20□ | 76 | 34 | 20.5 | 2 | M6×1 | 10 | M6×1 | 8.6 | 14 | 8.5 | 4H9 | 4.5 | 43 | 117 | 17H9 | 9 | 12 | 10.6 | 25 | 54 | 37 | 6.5 | 2.5 | 17 | 10 | 6 | 61 | 60 | 28 | M10×1.5 | 15 | M10×1 | 65 | 60 | 27.5 | 14 | 5 | 28.5 | 16 | 51 | 10 | 12 | M5×0.8 | 34.7 | 10.6 | M10×1 | RBA1006-X692 |

| MSQB30□ | 84 | 37 | 23 | 2 | M6×1 | 10 | M6×1 | 8.6 | 14 | 8.5 | 4H9 | 4.5 | 48 | 127 | 22H9 | 9 | 12 | 10.6 | 25 | 57 | 40 | 6.5 | 3 | 17 | 10 | 4.5 | 67 | 65 | 32 | M10×1.5 | 15 | M10×1 | 70 | 65 | 29 | 14 | 5 | 32 | 18.5 | 50 | 11.5 | 14 | 1/8 | 34.7 | 10.6 | M10×1 | RBA1006-X692 |

| MSQB50□ | 100 | 50 | 26.5 | 2 | M8×1.25 | 12 | M8×1.25 | 10.5 | 18 | 10.5 | 5H9 | 5.5 | 55 | 152 | 26H9 | 10 | 15.5 | 14 | 31.4 | 66 | 46 | 7.5 | 3 | 20 | 12 | 5 | 77 | 75 | 35 | M12×1.75 | 18 | M14×1.5 | 80 | 75 | 38 | 19 | 6 | 37.5 | 22 | 63 | 14.5 | 15 | 1/8 | 51.7 | 14 | M14×1.5 | RBA1411-X692 |

Applications

- Material handling and transfer systems

- Assembly lines

- Packaging machinery

- Robotic positioning systems

- Indexing tables

Benefits

- High precision and accuracy for demanding applications

- Increased load capacity for handling heavier workpieces

- Versatile mounting options for easy integration

- Smooth operation for consistent performance

- Adjustable angle range for application flexibility

- Compact design for space-saving installations

For detailed specifications, model options, or customized solutions, please refer to the provided dimension tables and ordering codes. Our technical support team is available to assist you in selecting the optimal MSQ Series Rotary Table for your specific application requirements.