Hered MA Series Mini Stainless Steel Cylinder

Hered Pneumatic Co., LTD.’s MA Series Mini Stainless Steel Cylinder is a compact, high-performance actuator designed for various industrial applications. Featuring a special-shaped two-way sealing structure, anti-collision pads, and corrosion-resistant construction, this cylinder offers exceptional durability and versatility.

Key Features

- Special-shaped two-way sealing structure with oil storage function

- Fixed anti-collision pads on front and rear covers to reduce reversal impact

- Multiple rear cover options for flexible installation

- Riveting roll package structure for reliable connection

- High-precision stainless steel tube for strength and corrosion resistance

- Magnetized for position sensing

Inner structure and material of major parts

| No. | Item | Material | No. | Item | Material |

| 1 | Nut | Carbon Steel | 9 | Piston | Aluminium Alloy |

| 2 | Piston Rod | S45C Durionise Grinding Rod | 10 | Piston O-ring | NBR |

| 3 | Front Cover O-ring | NBR | 11 | Magnet | Plastics |

| 4 | Bushing | Wear Material | 12 | Magnet Base | Aluminium Alloy |

| 5 | Front Cover Nut | Carbon Steel | 13 | Wearing Pad (Ring) | Wear Material |

| 6 | Front Cover | Aluminium Alloy | 14 | Back shim washer | Free Cutting Steel |

| 7 | Stainless steel tube | Stainless steel | 15 | Hex Nut | Carbon Steel |

| 8 | Cushion Gasket | NBR | 16 | Back Cover | Aluminium Alloy |

Specification

| Bore (mm) | 16 | 20 | 25 | 32 | 40 | 50 | 63 | |

| Motion Pattern | MSA/MTA | Single-acting | – | |||||

| MAR | – | Double-acting | ||||||

| MA/MAD/MAJ | Double-acting | – | ||||||

| MAC/MACD/MACJ | – | Double-acting and Buffer Type | ||||||

| Working Medium | Air | |||||||

| Operating Pressure | Double-acting | 0.1~1.0MPa(15~145Psi) | ||||||

| Single-acting | 0.2~1.0MPa(28~145Psi) | |||||||

| Proof Pressure | 1.5MPa(215Psi) | |||||||

| Working Temperature | -20~70°C | |||||||

| Working Speed | Single-acting: 50~800mm/s; Double-acting: 30~800mm/s | |||||||

| Stroke Tolerance Range | 0~150 (+1.0/0) >150(+1.4/0) | |||||||

| Buffer Type | MAC/MACD/MACJ Series: Adjustable buffer; Other Series: Bumper | |||||||

| Port Size | M5×0.8 | PT1/8 | PT1/4 | |||||

Models

| Model | Action Type | Buffer Type |

|---|---|---|

| MA/MAD/MAJ | Double-acting | Bumper |

| MAC/MACD/MACJ | Double-acting | Adjustable buffer |

| MSA/MTA | Single-acting | Bumper |

| MAR | Double-acting | Bumper |

Ordering Code of MA, MAC, MSA, MTA

Ordering Code of MAD, MACD, MAJ, MACJ

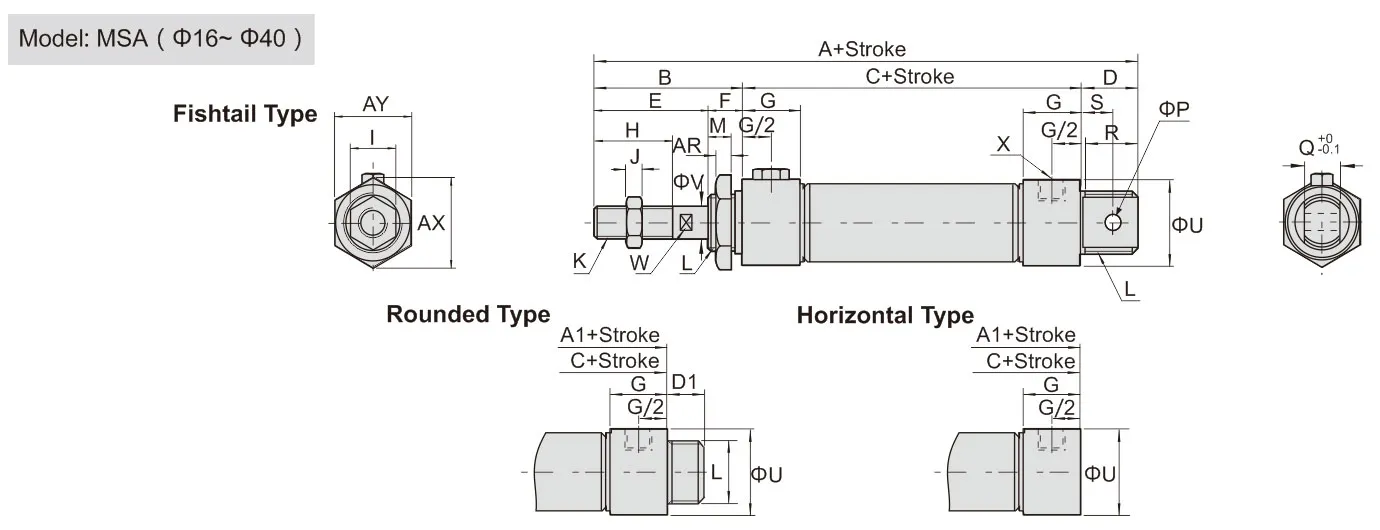

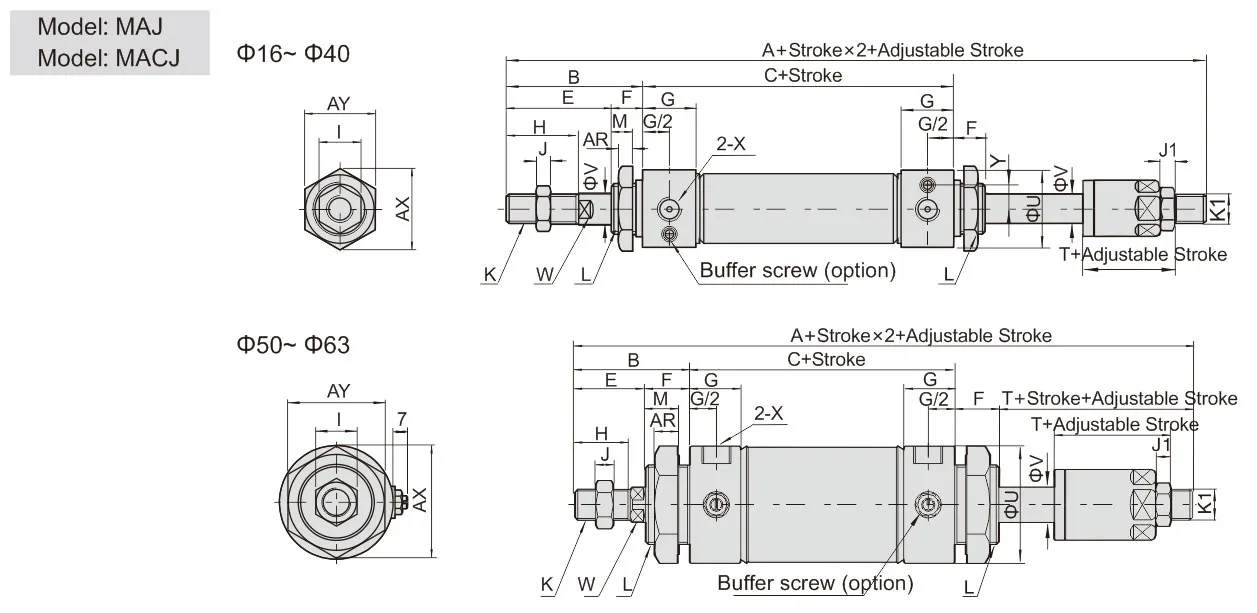

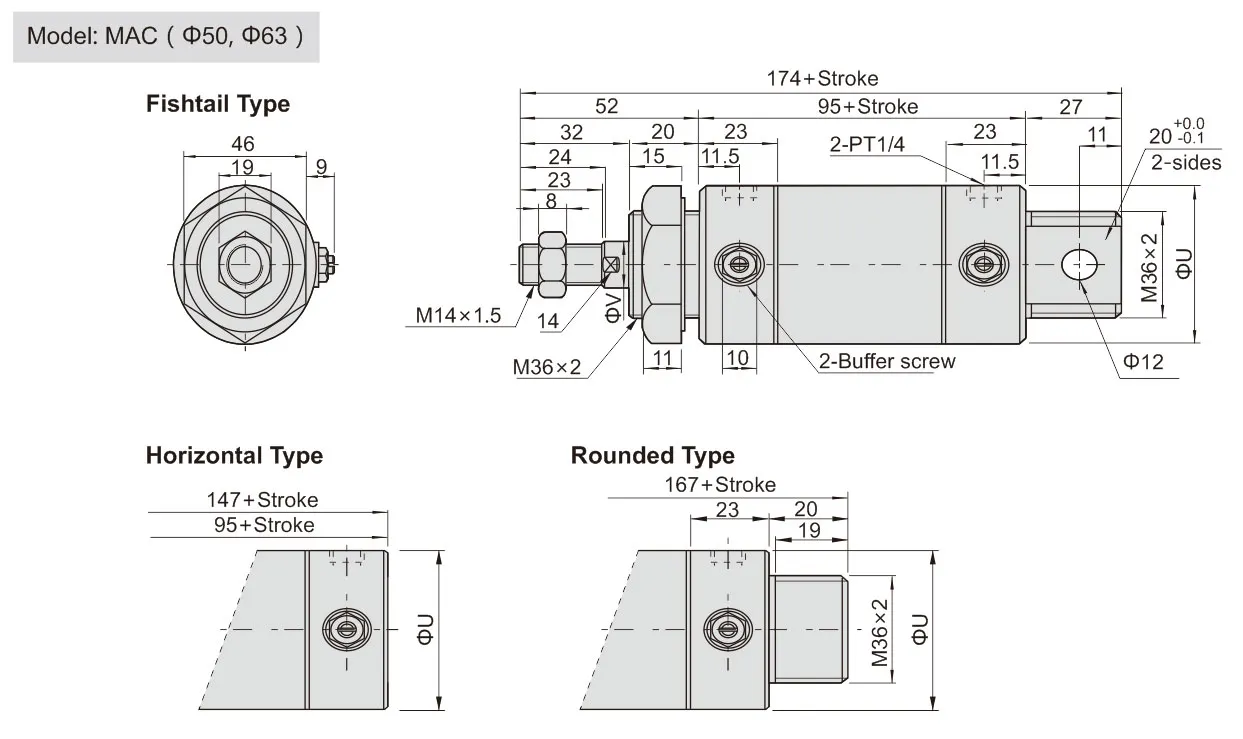

Overall Dimension

| Symbol | A | A1 | B | C | D | D1 | E | F | |||||||||

| Bore | ≤25 | ≤50 | ≤75 | ≤100 | ≤25 | ≤50 | ≤75 | ≤100 | ≤25 | ≤50 | ≤75 | ≤100 | |||||

| 16 | 129 | 139 | 154 | 164 | 113 | 123 | 138 | 148 | 38 | 75 | 85 | 100 | 110 | 16 | 16 | 22 | 16 |

| 20 | 152 | 162 | 177 | 187 | 131 | 141 | 156 | 166 | 40 | 91 | 101 | 116 | 126 | 21 | 12 | 28 | 12 |

| 25 | 156 | 166 | 181 | 191 | 135 | 145 | 160 | 170 | 44 | 91 | 101 | 116 | 126 | 21 | 14 | 30 | 14 |

| 32 | 162 | 172 | 192 | 192 | 135 | 145 | 165 | 165 | 44 | 91 | 101 | 121 | 121 | 27 | 14 | 30 | 14 |

| 40 | 164 | 174 | 194 | 204 | 137 | 147 | 167 | 177 | 46 | 91 | 101 | 121 | 131 | 27 | 14 | 32 | 14 |

| Bore | A | B | C | E | F | G | H | I | J | J1 | K | K1 | L | M | U | V | W | X | AR | AX | AY | Y | T |

| 16 | 135 | 38 | 60 | 22 | 16 | 10 | 16 | 10 | 5 | 5 | M6x1.0 | M6x1.0 | M16x1.5 | 14 | 21 | 6 | 5 | M5x0.8 | 6 | 25 | 22 | – | 16 |

| 20 | 153 | 40 | 76 | 28 | 12 | 16 | 20 | 12 | 6 | 6 | M8x1.25 | M8x1.25 | M22x1.5 | 10 | 27 | 8 | 6 | PT1/8 | 7 | 33 | 29 | 8.7 | 19 |

| 25 | 161 | 44 | 76 | 30 | 14 | 16 | 22 | 17 | 6 | 6 | M10x1.25 | M10x1.25 | M22x1.5 | 12 | 30 | 10 | 8 | PT1/8 | 7 | 33 | 29 | 10.2 | 21 |

| 32 | 161 | 44 | 76 | 30 | 14 | 16 | 22 | 17 | 6 | 6 | M10x1.25 | M10x1.25 | M24x2.0 | 12 | 35 | 12 | 10 | PT1/8 | 8 | 37 | 32 | 12 | 21 |

| 40 | 164 | 46 | 76 | 32 | 14 | 16.7 | 24 | 17 | 7 | 7 | M12x1.25 | M12x1.25 | M30x2.0 | 12 | 41.6 | 16 | 14 | PT1/8 | 9 | 47 | 41 | 15 | 21 |

| 50 | 195 | 52 | 95 | 32 | 20 | 23 | 24 | 19 | 8 | 7 | M14x1.5 | M12x1.25 | M36x2.0 | 15 | 53 | 16 | 14 | PT1/4 | 11 | 53 | 46 | – | 28 |

| 63 | 195 | 52 | 95 | 32 | 20 | 23 | 24 | 19 | 8 | 7 | M14x1.5 | M12x1.25 | M36x2.0 | 15 | 67 | 16 | 14 | PT1/4 | 11 | 53 | 46 | – | 28 |

| Symbol | A | A1 | B | C | D | D1 | E | F | G | H | I | ||||||

| Bore | ≤50 | 51-100 | ≥101 | ≤50 | 51-100 | ≥101 | ≤50 | 51-100 | ≥101 | ||||||||

| 16 | 139 | 164 | – | 123 | 148 | – | 38 | 85 | 110 | – | 16 | 16 | 22 | 16 | 10 | 16 | 10 |

| 20 | 162 | 187 | 212 | 141 | 166 | 191 | 40 | 101 | 126 | 151 | 21 | 12 | 28 | 12 | 16 | 20 | 12 |

| 25 | 166 | 191 | 216 | 145 | 170 | 195 | 44 | 101 | 126 | 151 | 21 | 14 | 30 | 14 | 16 | 22 | 17 |

| 32 | 172 | 197 | 222 | 145 | 170 | 195 | 44 | 101 | 126 | 151 | 27 | 14 | 30 | 16 | 16 | 22 | 17 |

| 40 | 174 | 199 | 224 | 147 | 172 | 197 | 46 | 101 | 126 | 151 | 27 | 14 | 32 | 14 | 16.7 | 24 | 17 |

| Bore | J | K | L | M | P | Q | R | S | U | V | W | X | AR | AX | AY |

| 16 | 5 | M6x1.0 | M16x1.5 | 14 | 6 | 12 | 14 | 9 | 21 | 6 | 5 | M5x0.8 | 6 | 25 | 22 |

| 20 | 6 | M8x1.25 | M22x1.5 | 10 | 8 | 16 | 19 | 12 | 27 | 8 | 6 | PT1/8 | 7 | 33 | 29 |

| 25 | 6 | M10x1.25 | M22x1.5 | 12 | 8 | 16 | 19 | 12 | 30 | 10 | 8 | PT1/8 | 7 | 33 | 29 |

| 32 | 6 | M10x1.25 | M24x2.0 | 12 | 10 | 16 | 25 | 15 | 35 | 12 | 10 | PT1/8 | 8 | 37 | 32 |

| 40 | 7 | M12x1.25 | M30x2.0 | 12 | 12 | 20 | 25 | 15 | 41.5 | 16 | 14 | PT1/8 | 9 | 47 | 41 |

| Bore | G | H | I | J | K | L | M | P | Q | R | S | U | V | W | X | AR | AX | AY |

| 16 | 10 | 16 | 10 | 5 | M6x1.0 | M16x1.5 | 14 | 6 | 12 | 14 | 9 | 21 | 6 | 5 | M5x0.8 | 6 | 25 | 22 |

| 20 | 16 | 20 | 12 | 6 | M8x1.25 | M22x1.5 | 10 | 8 | 16 | 19 | 12 | 27 | 8 | 6 | PT1/8 | 7 | 33 | 29 |

| 25 | 16 | 22 | 17 | 6 | M10x1.25 | M22x1.5 | 12 | 8 | 16 | 19 | 12 | 30 | 10 | 8 | PT1/8 | 7 | 33 | 29 |

| 32 | 16 | 22 | 17 | 6 | M10x1.25 | M24x2.0 | 12 | 10 | 16 | 25 | 15 | 35 | 12 | 10 | PT1/8 | 8 | 37 | 32 |

| 40 | 16.7 | 24 | 17 | 7 | M12x1.25 | M30x2.0 | 12 | 12 | 20 | 25 | 15 | 41.5 | 16 | 14 | PT1/8 | 9 | 47 | 41 |

| Bore | A | B | C | E | F | G | H | I | J | K | L | M | U | V | W | X | AR | AX | AY | Y |

| 16 | 136 | 38 | 60 | 22 | 16 | 10 | 16 | 10 | 5 | M6x1.0 | M16x1.5 | 14 | 21 | 6 | 5 | M5x0.8 | 6 | 25 | 22 | – |

| 20 | 156 | 40 | 76 | 28 | 12 | 16 | 20 | 12 | 6 | M8x1.25 | M22x1.5 | 10 | 27 | 8 | 6 | PT1/8 | 7 | 33 | 29 | 8.7 |

| 25 | 164 | 44 | 76 | 30 | 14 | 16 | 22 | 17 | 6 | M10x1.25 | M22x1.5 | 12 | 30 | 10 | 8 | PT1/8 | 7 | 33 | 29 | 10.2 |

| 32 | 164 | 44 | 76 | 30 | 14 | 16 | 22 | 17 | 6 | M10x1.25 | M24x2.0 | 12 | 35 | 12 | 10 | PT1/8 | 8 | 37 | 32 | 12 |

| 40 | 168 | 46 | 76 | 32 | 14 | 16.7 | 24 | 17 | 7 | M12x1.25 | M30x2.0 | 12 | 41.6 | 16 | 14 | PT1/8 | 9 | 47 | 41 | 15 |

| 50 | 199 | 52 | 95 | 32 | 20 | 23 | 24 | 19 | 8 | M14x1.5 | M36x2.0 | 15 | 53 | 16 | 14 | PT1/4 | 11 | 53 | 46 | – |

| 63 | 199 | 52 | 95 | 32 | 20 | 23 | 24 | 19 | 8 | M14x1.5 | M36x2.0 | 15 | 67 | 16 | 14 | PT1/4 | 11 | 53 | 46 | – |

Construction

The MA series cylinders feature high-quality components, including:

- Stainless steel tube body

- Aluminum alloy front and rear covers

- Carbon steel piston rod with durionise grinding

- NBR seals and cushion gaskets

- Wear-resistant materials for bushings and wearing pads

Applications

- Industrial automation

- Food and beverage processing

- Pharmaceutical manufacturing

- Chemical processing

- Packaging machinery

Benefits

- Compact design for space-saving installations

- Corrosion-resistant construction for harsh environments

- Reduced impact and smooth operation

- Flexible mounting options

- Long service life and low maintenance

- Position sensing capability

For detailed specifications, model options, or customized solutions, please refer to the provided dimension tables and ordering codes. Our technical support team is available to assist you in selecting the optimal MA Series Mini Stainless Steel Cylinder for your specific application requirements.